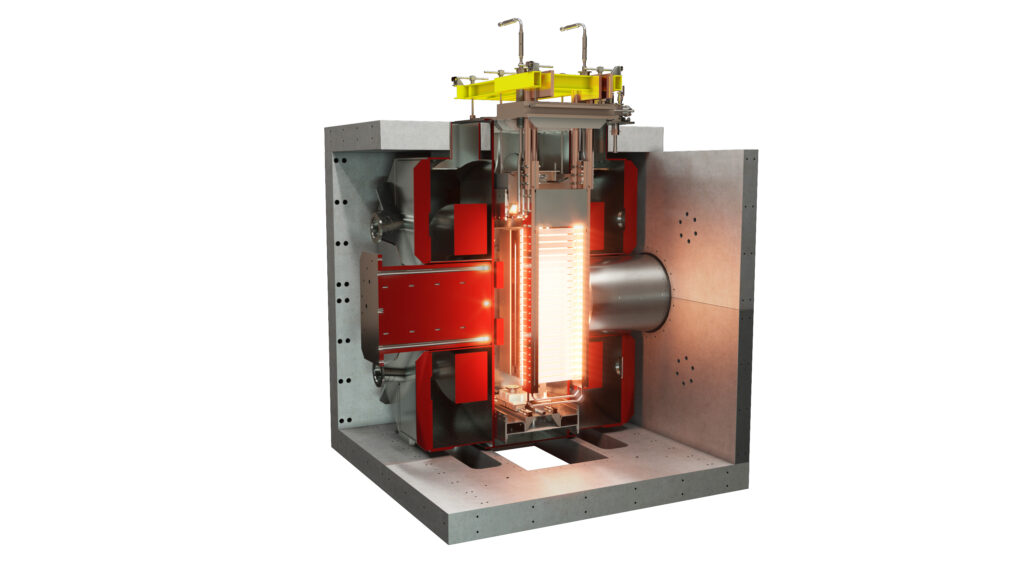

When it opens in 2022, CHIMERA will be the only device in the world able to subject fusion component prototypes to the combination of high heat flux with static and pulsed magnetic fields within a vacuum or inert atmosphere – conditions that will be faced in large fusion devices such as ITER, and in future fusion commercial power plants.

In-vessel fusion components like the tritium-breeding blanket, divertor and diagnostic modules are expected to be tested. Optical Digital Image Correlation and laser metrology will be used to map 3D surface deformations and damage resulting from CHIMERA’s harsh testing environment. In addition to providing invaluable test results, techniques will be used to generate and synchronise digital twin components – predictive models and simulations crucial to the design and qualification of fusion power plants. This ‘virtual qualification’ is a key CHIMERA capability enabling virtual testing of components under conditions that cannot be recreated in a physical experiment.

Damon Johnstone, UKAEA’s Head of Operations, Fusion Technology Business Unit and Head of the Fusion Technology Facility, said: “CHIMERA is a unique, world-first facility in which we will be able to simulate the extreme conditions found within a fusion power plant, even without any nuclear fusion reactions taking place.

“This will enable a step change in our ability to verify and test components for all UK and international fusion research programmes. It therefore represents a hugely important national capability, enabling industry in the UK and internationally to design and qualify components for future commercial fusion power plants.”

Key Technical Specifications

- Component size: Up to 1.7m x 0.5m x 0.9m

- Testing chamber: Vacuum or inert gas

- Water cooling: Inlet 150°C, 1.5MPa, or Inlet 200°C– 385°C, 650 litres/min, 15.5MPa

- Surface heating: 0.5MW/m<sup>2</sup> over ~0.8m<sup>2</sup> (1MW/m<sup>2</sup> in a later phase)

- Simulated volumetric heating: Power up to 100kW (700kW in a later phase)

- Static magnetic field: 4 Tesla central field

- Magnetic impulse simulating plasma disruption: dB/dt ~ 12 T/s

- Static magnet (horizontal field): Split-pair superconducting magnet with NbTi coils in liquid Helium baths

- Ramp-up/down time: ~ 8 hours

- Pulsed magnet (vertical field): Water cooled copper conductor

Diagnostics

- Integrated data acquisition system enabling thorough diagnosis of performance and abundant engineering data for high-fidelity model validation

- Capacity for up to 200 channels of onboard mock-up instrumentation (analogue or digital) – temperature, strain, potential probes, hall probes, etc.

- High frame rate in-vessel viewing camera

- Mock-up capacitive position sensors

- Mock-up 6 degree of freedom force and torque measurement

- Digital image correlation (DIC) at component scale