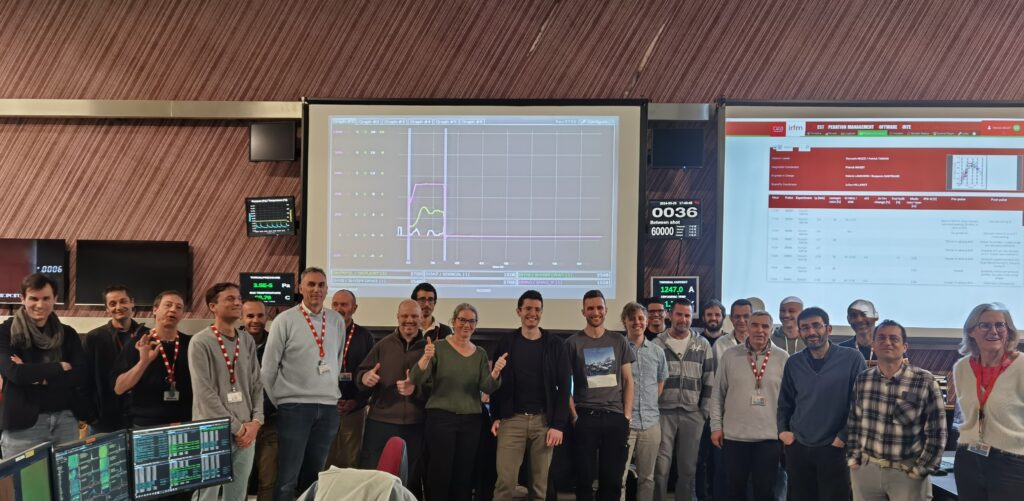

Superconducting tokamak WEST at French CEA closes in on 1000-second pulses after completing ITER-grade divertor

Receive our latest blog posts directly in your inbox!